Streamline Your Recycling Refine With Stacking Conveyors: a Comprehensive Equipment Review

In today's hectic globe, efficiency is every little thing. When it comes to reusing, discovering ways to improve the process can have a considerable influence on performance and overall effectiveness. Go into stacking conveyors. These versatile pieces of equipment use a thorough service to enhance your reusing procedures. With a series of kinds readily available, each with their own special functions and benefits, stacking conveyors can transform the means you manage products. How specifically do they integrate right into your existing processes? And which sectors can benefit one of the most from their usage? In this detailed tools introduction, we will discover the solution to these concerns and even more, supplying you with the understandings you need to take your recycling operations to the following degree.

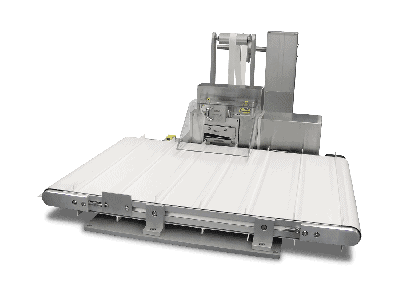

Kinds Of Piling Conveyors

There are a number of sorts of piling conveyors available out there today, each designed to meet particular product handling requirements. One such kind is the radial piling conveyor, which includes a pivot point that allows it to rotate in a round movement. This enables it to develop a large stockpile in a radial pattern, making it perfect for applications where a variety of products need to be accumulated in a circular formation.

An additional kind is the telescopic stacking conveyor, which can pull back and prolong to fit different accumulation lengths. This versatility makes it ideal for applications where space is limited or where numerous stockpiles of varying sizes need to be produced.

Last but not least, there are track-mounted stacking conveyors that can be quickly transported and maneuvered around job websites (stacking conveyors for sale). These conveyors are typically used in industries such as construction and mining, where the conveyor needs to be moved often

Trick Attributes and Benefits

Piling conveyors use a series of key features and benefits that enhance material dealing with effectiveness and improve procedures. These conveyors are designed to stack and organize products in a portable and effective fashion, permitting for very easy access and transport. One of the key attributes of stacking conveyors is their capacity to up and down stack products, optimizing using available room. This not just minimizes the demand for additional storage space locations yet likewise enables far better company and ease of access of materials.

Another important attribute of stacking conveyors is their flexible height and disposition. This permits operators to quickly tailor the conveyor to fulfill the certain demands of their operation, whether it's filling materials onto vehicles or feeding them right into handling tools. The capacity to readjust the conveyor's elevation and inclination also makes certain a continuous and smooth flow of materials, minimizing interruptions and downtime.

Along with their adjustable attributes, piling conveyors are also geared up with numerous safety and security systems (stacking conveyors for sale). These include emergency stop buttons, safety and security guards, and overload defense systems, every one of which assistance avoid mishaps and make certain the health of employees and drivers

The advantages of making use of stacking conveyors are numerous. They considerably improve material dealing with effectiveness by minimizing hand-operated labor and increasing efficiency. They additionally aid streamline operations by eliminating the requirement for multiple devices and minimizing the moment and effort needed to relocate and arrange products.

Additionally, piling conveyors add to a cleaner and much safer workplace. By successfully stacking materials, they lower clutter and the risk of accidents caused by stumbling or falling objects. They additionally reduce dirt and debris, improving air top quality and lowering the danger of breathing issues for workers.

Integration Into Recycling Procedures

Integration of piling conveyors right into recycling operations enhances product dealing with efficiency and promotes the seamless activity and company of recyclable materials. By integrating stacking conveyors into their procedures, recycling centers can simplify the flow of products, decreasing manual handling and minimizing the risk of accidents or injuries. Stacking conveyors enable the efficient movement of recyclables from one area to an additional, such as from sorting to baling or from baling to storage. This gets rid of the demand for additional tools or manual work to move materials, conserving time and resources.

Moreover, the assimilation of piling conveyors allows reusing centers to enhance their room application. These conveyors can be designed to fit within existing layouts, making it much easier to make the most of readily available room and lessen blockage. By effectively piling materials, stacking conveyors can assist reusing facilities make the most of read more their storage space areas, reducing the requirement for additional storage area or the use of off-site centers.

Along with enhancing product dealing with efficiency, stacking conveyors additionally add to the company of recyclable products. By developing a methodical flow of materials, these conveyors aid make certain that different kinds of recyclables are kept separate and correctly arranged. This assists recycling centers keep the high quality of their products and fulfill the specifications of end-users, eventually enhancing the worth and marketability of the recycled items.

Performance and Productivity Increase

The incorporation of stacking conveyors right into recycling procedures significantly enhances general effectiveness and efficiency. These specific tools streamline the recycling procedure by automating the motion of materials, lowering manual work and boosting throughput.

One essential factor adding to the effectiveness boost is the capability of piling conveyors to deal with a huge quantity of materials in a brief period of time. These conveyors can carry and pile products vertically, permitting much more efficient use of area in recycling centers. This removes the requirement for added handling tools or hands-on sorting, saving both time and sources.

Stacking conveyors also boost performance by lowering the danger of product contamination. With hands-on handling, there is a higher opportunity of cross-contamination, which can result in increased sorting time and decreased item top quality. By automating the process, stacking conveyors minimize human mistake and ensure a greater degree of uniformity in material handling.

Furthermore, stacking conveyors can be incorporated with other reusing equipment, such as shredders or separators, even more improving the recycling process. This combination allows for a smooth transfer of products between different phases of the reusing procedure, getting rid of traffic jams and maximizing total efficiency.

Industries That Can Benefit From Stacking Conveyors

Various industries can considerably gain from the use of piling conveyors in their operations. These flexible machines supply a series of advantages that can enhance effectiveness, performance, and overall success. One sector that can gain from stacking conveyors is the mining market. In mining operations, products such as coal, ore, and accumulations require to be carried and stocked successfully. Stacking conveyors can take care of big quantities of product, permitting seamless transport and storage. The building and construction industry is an additional go to the website industry that can profit from these conveyors. Building and construction sites typically call for the activity of hefty products such as sand, gravel, and concrete. Stacking conveyors can streamline this procedure, lowering manual work and raising efficiency. In addition, the reusing sector can significantly benefit from making use of piling conveyors. With the increasing emphasis on sustainability, reusing plants require reliable equipment to manage and sort different kinds of waste. Stacking conveyors can help transport and organize recyclable products, making the recycling procedure much more cost-effective and structured. On the whole, piling conveyors have a variety of applications and can profit sectors that call for effective material handling and transportation.

Final Thought

In verdict, piling conveyors provide a streamlined solution for reusing procedures. By getting rid of individual pronouns and keeping an academic writing style, this post has offered an extensive introduction of piling conveyors and their significance in recycling operations.

One of the essential attributes of stacking conveyors is their capability to up and down stack materials, making best use of the usage of available room (stacking conveyors for sale).Integration of piling conveyors into recycling procedures boosts product this article dealing with effectiveness and promotes the seamless movement and organization of recyclable materials. By integrating stacking conveyors into their procedures, reusing facilities can streamline the circulation of materials, lowering hands-on handling and lessening the risk of crashes or injuries. By successfully stacking products, piling conveyors can aid reusing facilities make the most of their storage areas, reducing the need for additional storage space or the use of off-site centers

In enhancement to boosting material managing effectiveness, stacking conveyors additionally add to the company of recyclable materials.